Resistance touch screen customization

Advantages of resistive touchscreens.

•Resistive touchscreens are highly accurate down to the pixel dot level and are suitable for resolutions up to 4096x4096.

•The screen is unaffected by dust, moisture and oil and can be used in low or high temperature environments.

•Resistive touch screens use pressure sensing, can be touched with any object, can be used with gloves and can be used for handwriting recognition.

•Resistive touchscreens are also less expensive due to the more mature technology.

Disadvantages of resistive touchscreens.

•Resistive touch screens can usually only achieve single point touch. If designed for multi-touch, when two points are pressed at the same time, the pressure on the screen becomes unbalanced, resulting in touch errors and making it harder to achieve multi-touch.

•Resistive touch screens are more susceptible to damage from scratches and other causes that affect the touch function and appearance of the screen.

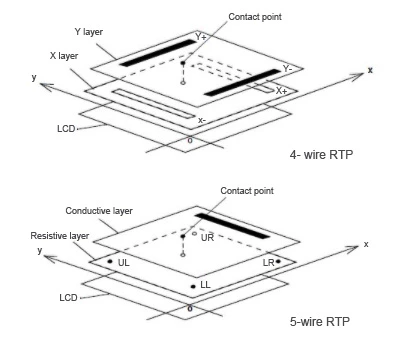

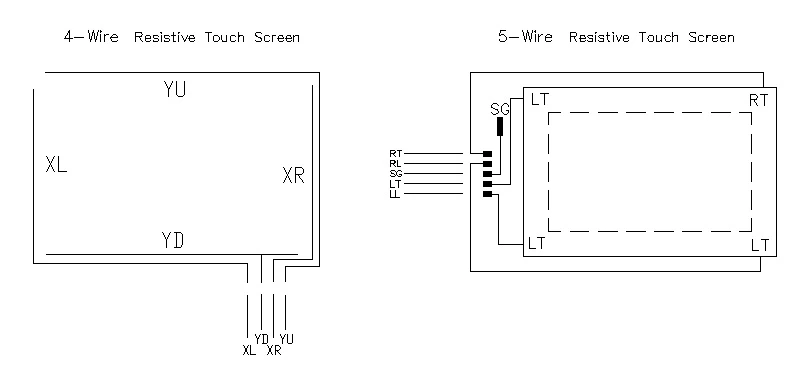

4-wire resistive touch modules

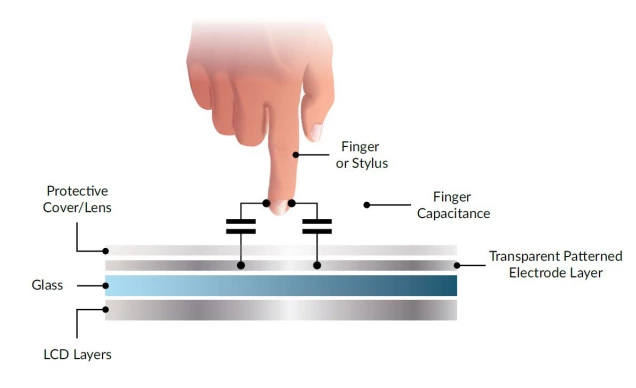

4-wire RTP: It has a relative cost advantage. It has an Indium Tin Oxide (ITO) resistive coating on the inside of the touch layer to form the X and Y axes. As soon as pressure is applied, the voltage changes and the coordinates of the X and Y axes are calculated using a voltage divider.

A disadvantage of the 4-wire RTP is that certain factors can degrade the linearity and accuracy of this axis, including external environmental conditions and high frequency operation. Occasional recalibration may be required to maintain the accuracy of the touch points. Also, as the top layer material is a thin film, scratches and nail marks on the exterior will become more visible after extended use.

Occasional recalibration may be required to maintain the accuracy of the touch points. Also, as the top layer material is a thin film, scratches and nail marks on the exterior will become more visible after extended use.

5-wire resistive touch modules

The structure and design philosophy of a 5-wire RTP is similar to that of a 4-wire RTP. In a 5-wire resistive touch screen, only the bottom layer is used to generate the X and Y axis coordinates, which we call the resistive layer. The top layer is used as a purely conductive layer, usually made from a nickel-gold plated material for better durability. As the top layer is not used for one of the axes, this results in excellent stability, durability, sensitivity and reliability.

Some advantages of the 5-wire RTP are that a constant level of accuracy is maintained even if the top layer is damaged, and that the tactile response and accuracy are not affected by harsh environmental conditions. However, it is obviously more expensive and more difficult to manufacture.

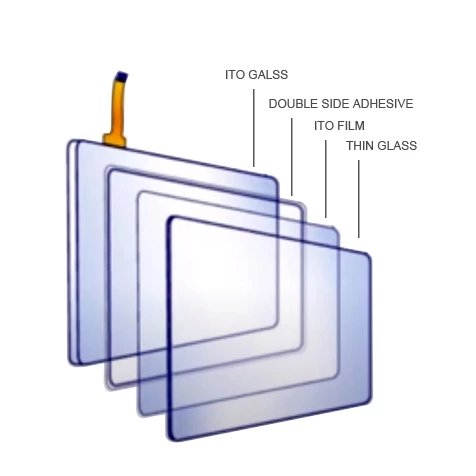

G+G Resistive Touch Modules

G+G resistive touch modules are the perfect solution to the problem of using RTP in harsh environments where corrosive solvents and liquids can damage the ITO film itself. Of course, it is a more complex process and we have experience with small quantities.