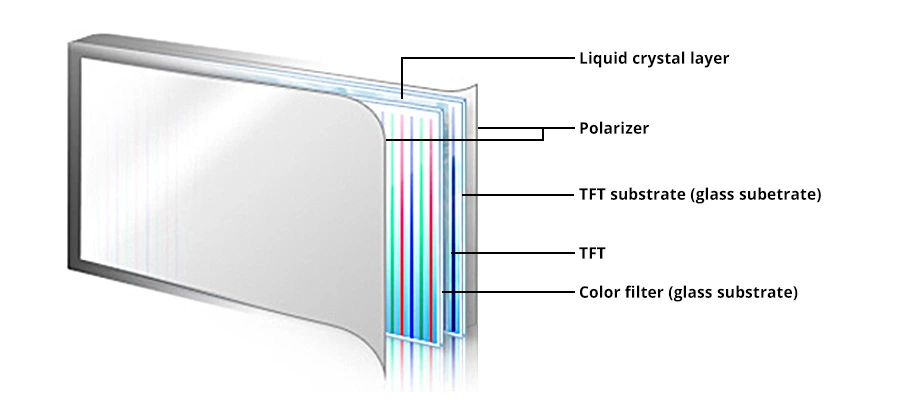

LCD panel structure

TFT LCD panel is the core device of liquid crystal display, it is composed of two pieces of glass, the upper layer of glass colour filter, we call CF, cloth with transparent electrodes; the middle is the crystal filling layer; the lower glass is with signal electrodes, alignment electrodes, thin film transistors of the substrate glass, we call ITO glass.The production process of TFT LCD panel is still relatively complex, and any changes to it must be made with care.

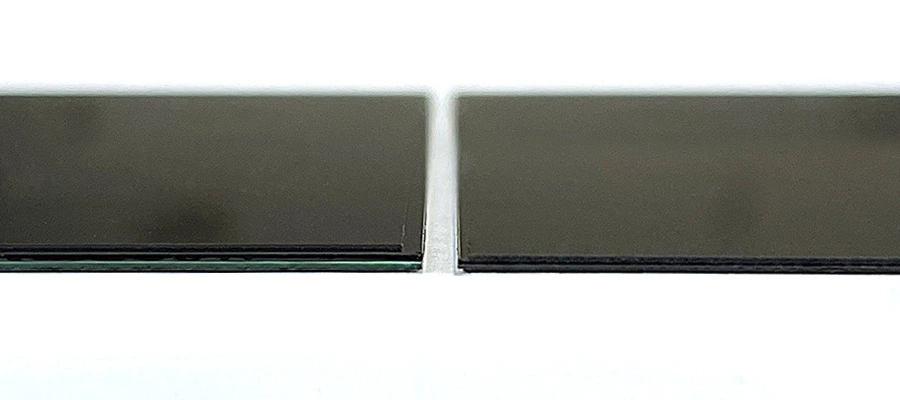

You may need a thinner TFT LCD MODULE, it may be a design requirement or it may be necessary due to structural constraints. However, TFT modules require backlight modules and polarisers which also take up a certain thickness. In as thin as possible after the choice of backlight and polarizer, if still can not meet your requirements, then we can also rely on the existing program, TFT LCD panel for thinning, such as a single piece of glass 0.5mm, we can thin down to 02-0.3mm. you know the TFT LCD panel is composed of two pieces of glass, the middle layer is filled with liquid crystal, so the original 1.0mm LCD panel, we can thin it down to 0.4-0.6mm, which is very valuable for the overall thickness.

LCD Panel Thinning Process

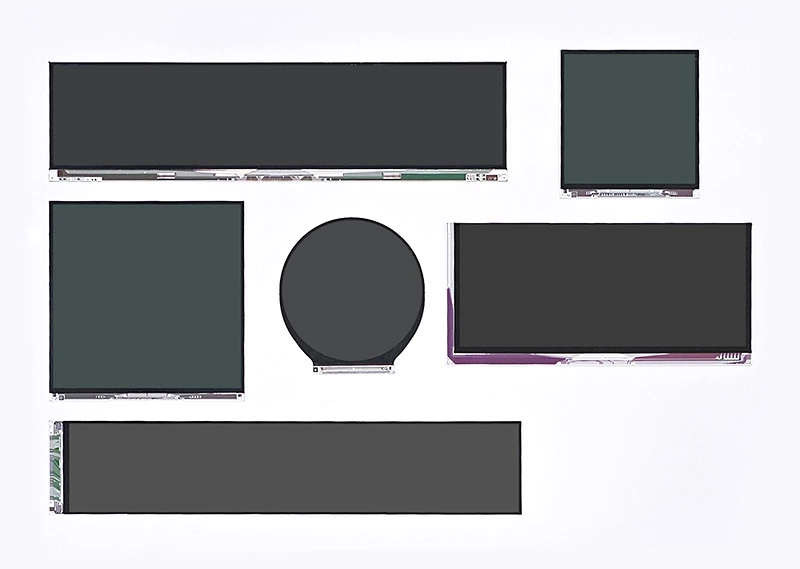

We can cut an off-the-shelf TFT LCD panel and change its original shape, for example, from a 16:9 screen to a 16:6 screen, from a 4:3 screen to a 4:2 screen, from a 3:2 screen to a 1:1 square. And so on and so forth. But not all LCD panels are suitable for cutting, it depends on the way the LCD panel is oriented, the circuit design, so its solution formation is something we need to evaluate and experiment with.

3.5 inch cut to 2.9 inch bar LCD module

15.6 inch cut to 13.9 inch bar LCD module

The majority of TFT LCD panels are fixed in size and resolution, but if you need a custom size or special resolution that is not available on the market, you can come to us for an assessment.We will provide you with the right solution to meet your needs and make your product cost unique in the market. However, customising a brand new LCD screen requires a large number of orders to be supported and expensive tooling costs, so if your order is small this may not be suitable. For larger orders, we will determine which generation line is most economical to produce on based on the size of the LCD panel, depending on your requirements. We will also look at tooling costs, minimum order quantities and unit prices.

Customers commissioned us to open the LCD mold

*The above pictures are real cases of our customized products for customers, in order to protect the product and customer safety, we only intercept the partial display, please understand.

If you have a very good idea and need a very special LCD module, want it thinner, want a special shape, please contact our team, don't hesitate.We'll do our best and think of everything we can do for you:

70+ engineers work for DISEA, most of them are from industry leaders of TFT LCD module, such as Tianma, BOE-Varitronix, etc. Each of our Core Team Members has 15 years of industry experience.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.