TFT LCD backlight module customization

The backlight is also a core component of the LCD module, unlike OLED displays, TFT LCD panels do not emit light themselves, it is a passive device, TFT LCD is a transmissive panel and needs a backlight to provide light. A good backlight module can provide even light and make the TFT LCD module display more uniform and detailed.

Disea can customize backlight in various specifications. In addition to the mechanical structure such as size/shape, we have this very rich experience in brightness level, NTSC, colour, drive circuit, heat dissipation, life time, power consumption control, cables, etc.

Brightness:

100~2000 nits, of course, subject to different sizes and structures, different products will have different brightness ceilings. For most of the products, we can achieve 1000nits to meet the requirement of sunlight readability.

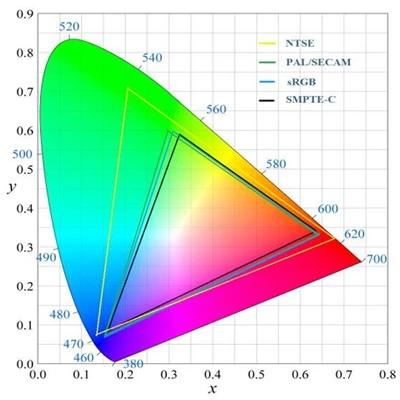

NTSC:

For the traditional backlight industry, it is difficult to significantly increase the value of NTSC, we have been experimenting with quantum dot technology, which can easily break through 100% NTSC. it makes the vividness of the picture better and the colour transition in the picture more natural.

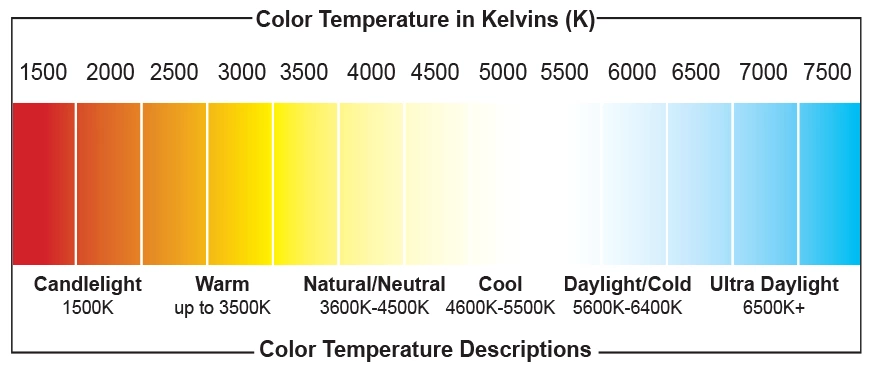

Colour Temperature in Kelvins:

The most widely used backlight for TFT LCD is white. Based on white, there is positive white at around 5500K, warm white (yellowish) at 3500K and also cool white (cold) at 6500K.We can choose the right colour LED in a combination of colours depending on your preference, or UI settings.

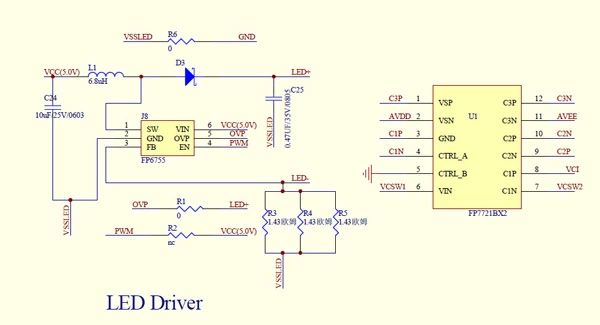

Driver circuit:

The small size of the backlight requires a relatively low voltage and current, and most motherboards can provide him with sufficient voltage and current values. And some high brightness requirements of the product or for larger sizes there may be dozens of LEDs present, then he may need a very high voltage or very large currents it is necessary to use the backlight drive circuit, we will also provide the drive circuit for this part of the product to adapt to the customer's output requirements, to reduce the secondary development cycle.

Heat dissipation:

Heat dissipation:

For high-brightness products, its power consumptionis often large, heat generation also rises, it is necessary to have a better heat dissipation structure, which needs to be considered in the backlight design out, advance design of reasonable heat dissipation structure, increase the heat dissipation film, the use of aluminum substrate, etc.

Power consumption:

Compared to TFT LCD, the power consumption of the backlight is much larger. It can be said that the biggest power consumption of LCM lies in the backlight. Between brightness and power consumption, some customers choose power consumption because they may be handheld products that need battery power and cannot have too much power consumption. Very often, we also increase the brightness without increasing the power consumption by means of additional films, such as DBEF, brightening films, etc.

Compared to TFT LCD, the power consumption of the backlight is much larger. It can be said that the biggest power consumption of LCM lies in the backlight. Between brightness and power consumption, some customers choose power consumption because they may be handheld products that need battery power and cannot have too much power consumption. Very often, we also increase the brightness without increasing the power consumption by means of additional films, such as DBEF, brightening films, etc.

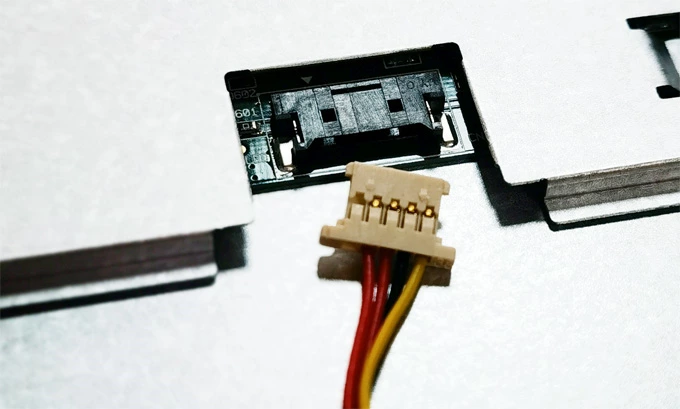

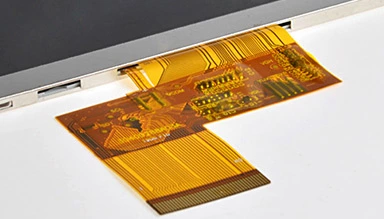

Cables:

Backlighting also requires cables, either through an FPC connected to the LCD's FPC and controlled through a port, or a separate cable that controls it through a connector. It depends on the structure of your product. Of course, if the current is higher, we still prefer to control it with a cable, which will be more secure.