IPS,High Birghtness,Touch Control and Optical bonding

Why choose IPS?

Unlike the TN technology used in conventional panels, TN panels can experience grey scale flip at certain angles, resulting in color shifts and obscuring the display's content. However, IPS panels ensure that the display's content may be viewed flawlessly from any angle. This type of full-viewing screen has been widely adopted, and the majority of mobile phones and televisions now utilize them.

Why choose high brightness?

We live in a world that is bright and full of colors. How information is shown on the screen is very important. No one wants to look at a picture that is dull and gray. So, our high-brightness displays have 1000 cd/m2 and can show a clear picture even when you're outside. High brightness is the key to being able to read outside, and Disea technologies come standard with high brightness.

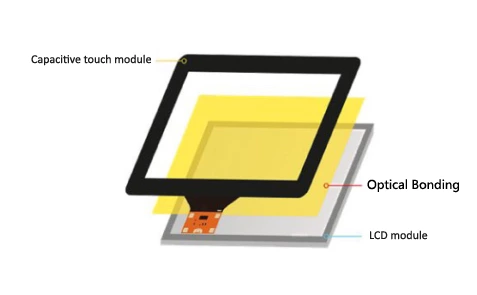

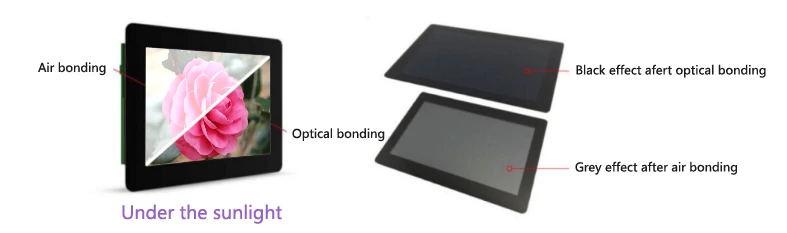

What's Optical bonding?

Optical bonding is the process of using a liquid adhesive, gel, to attach the touch panel or just the protective glass to the screen. In general, this process makes the module's optical performance, durability, and reliability better.

If you want to make sure that your display has better optical performance and is very durable, you should choose one of our high brightness IPS displays with optical bonding. The combination of these technologies makes for a very competitive product and product performance.

*You might not understand why optical bonding improves optical performance. During the optical bonding process, an optical grade adhesive is used to stick the glass to the top of the display. It gets rid of the air gap that is usually between the touch panel and the screen. When the air gap is gone, there are fewer internal surfaces that reflect light, which makes the optical performance better. This effect makes things easier to read by reducing reflections and adjusting contrast.

Why use an industrial capacitive screen controller?

We can use experienced engineers and industrial capacitive screen controllers to figure out how touch works. Touch screens can be used with water or with gloves on. We don't have to do much to make the touch function work on each device. Our touch screens can meet most industrial and medical standards because they use a high-quality capacitive screen controller.

Why use a projected capacitive touch screen?

PCAP is the most popular and cutting-edge touchscreen technology. It gives people a simple way to interact with the display. Most mobile phones, tablets, and other handheld devices have this type of touchscreen. With this technology, you don't even have to think about how to tap, scroll, zoom, pinch, or flick. If you're making an app that needs to work well with your device and have an easy-to-use user interface, you don't need to look any further than these new displays.

Here are the most important things about these touch screens:

1. The thickness of the cover glass can be 0.55, 0.7, 1.1, 1.8, 2.0, 3.0, 4.0 (mm), etc.

2. The cover glass can meet impact standards IK07-IK09 (Of course, it is also related to the size of the cover glass, please consult our engineers for details).

3. Can be used with a wide range of gloves, not just rubber gloves but also cotton gloves.

4. For marine applications, it can work with water, even salt water.

5. Can use up to 10 fingers at once.

6. Excellent EMC, EMC, ESD, RS, CS performance.

Now you can easily select the right display for your application and if you have questions or queries, our experienced team is on hand to assist you.